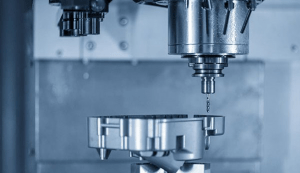

CNC milling takes place exclusively on milling machines characterised by their solid construction and the use of modern technological solutions. We have 3-, 4- and 5-axis milling machines thanks to which it is possible to manufacture even the most complicated details with maximum dimensions of 1300x650x600 mm and weight of 1000kg. We have machines with a pallet exchanger for serial production, thanks to which we ensure precise and effective execution of the service. Our priority is the quality of the service provided, as well as flexibility to meet customer requirements. Each process follows strictly developed rules that allow even the most demanding projects to be realised.

CNC milling

CNC milling

Advantages of CNC milling

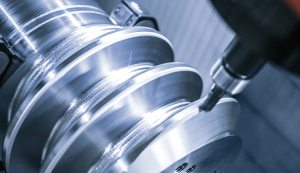

CNC services such as milling enable even very complex workpiece shapes to be created with high precision. The method of computer numerical control of the equipment is fully automated, which makes it possible to achieve effects in a short time that are difficult to achieve with manual control. Advantages of CNC milling that deserve special attention are:

- high-precision machining,

- a perfect reproduction of the design brief,

- the reproducibility of components, without any reduction in production quality,

- reduced material consumption, thanks to precisely defined parameters,

- flexibility of the production line,

- universality - CNC services enable metal, steel and plastic milling.

What is CNC milling?

CNC (Computerised Numerical Control) is the term for a control system that can be freely programmed to give the customer a product with the required dimensions, shape and surface properties. CNC milling is one of the machining methods and involves machining a stationary workpiece while the tool of the milling machine performs a rotary movement. The rotating tool blades cut the top layer of the part until the desired effect is achieved. CNC milling is fully automated, ensuring maximum precision, making it a popular method in many manufacturing facilities.