Modern turning machines allow CNC turning of both individual components, including but not limited to prototypes, as well as series production. CNC turning is often used not only for prototyping, but also for reproducing parts of machines and devices. We have machines that enable us to turn and mill any shape in a single fixture. This results in better manufacturing tolerances and shorter lead times.

CNC machine turning

CNC machine turning

Our services

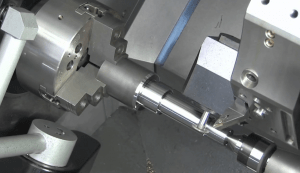

CNC precision turning

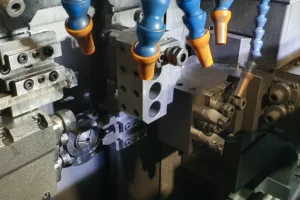

Our specialists use the highest quality turning tools, enabling the greatest possible precision. By using modern equipment, our company guarantees the stability and repeatability of the process. We prepare an individual offer for each customer, based on their requirements and needs.

Professional turning of any shape

We have machines that enable us to turn any shape at the same time. We respect our customers' time and place great emphasis on meeting deadlines.

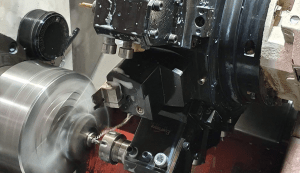

High-volume turning

We have multi-axis, twin-spindle automatic lathes including driven tools and bar feeder, for series production, maximum turning diameter - ⌀35.

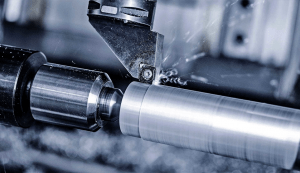

CNC turning - what is it?

CNC turning is - like milling - a method of computerised material processing. It involves separating a layer of material from the workpiece using a turning knife. The blade does not move - only the workpiece is moved. The result is a workpiece with a cylindrical, conical or spherical shape.